AMP PRESS

Patent Pending

Out now!

For pricing and availability in your region see here

Demonstration

Introduction

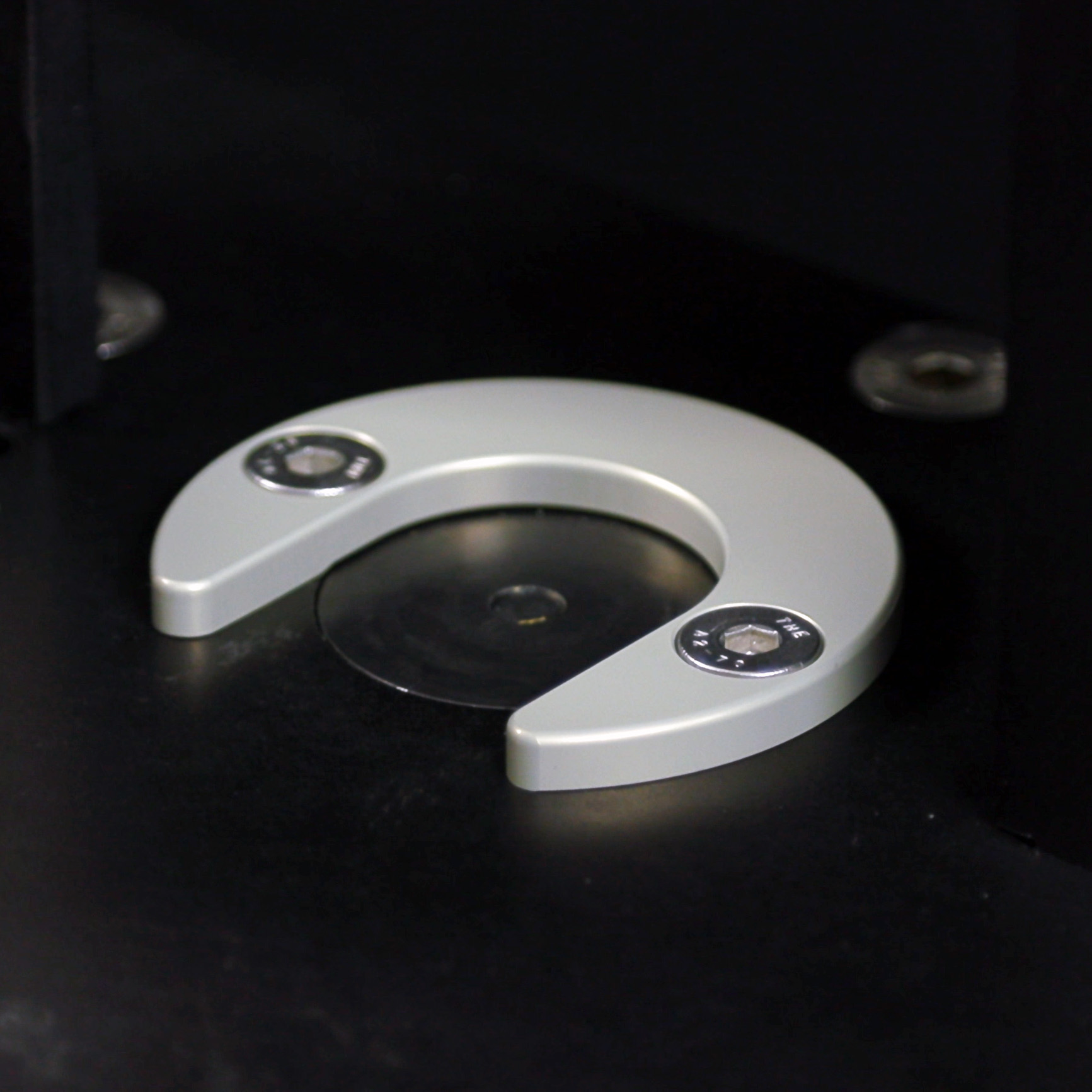

The AMP Press combines a motor driven ram, a distance sensor, and a load cell to deliver extremely accurate and precise Force / Distance bullet seating measurements. It is designed for use with inline bullet seating dies.

For the first time, this data can be stored and sorted according to a multitude of variables. This allows users to enhance their case preparation, so as to achieve more consistent "neck tension". It also allows users to batch their loads accordingly.

Users can create cartridge profiles and store sessions for each caliber. Current bullet seating sessions can be compared to previous ones to accurately see how loads are changing (if at all) over time.

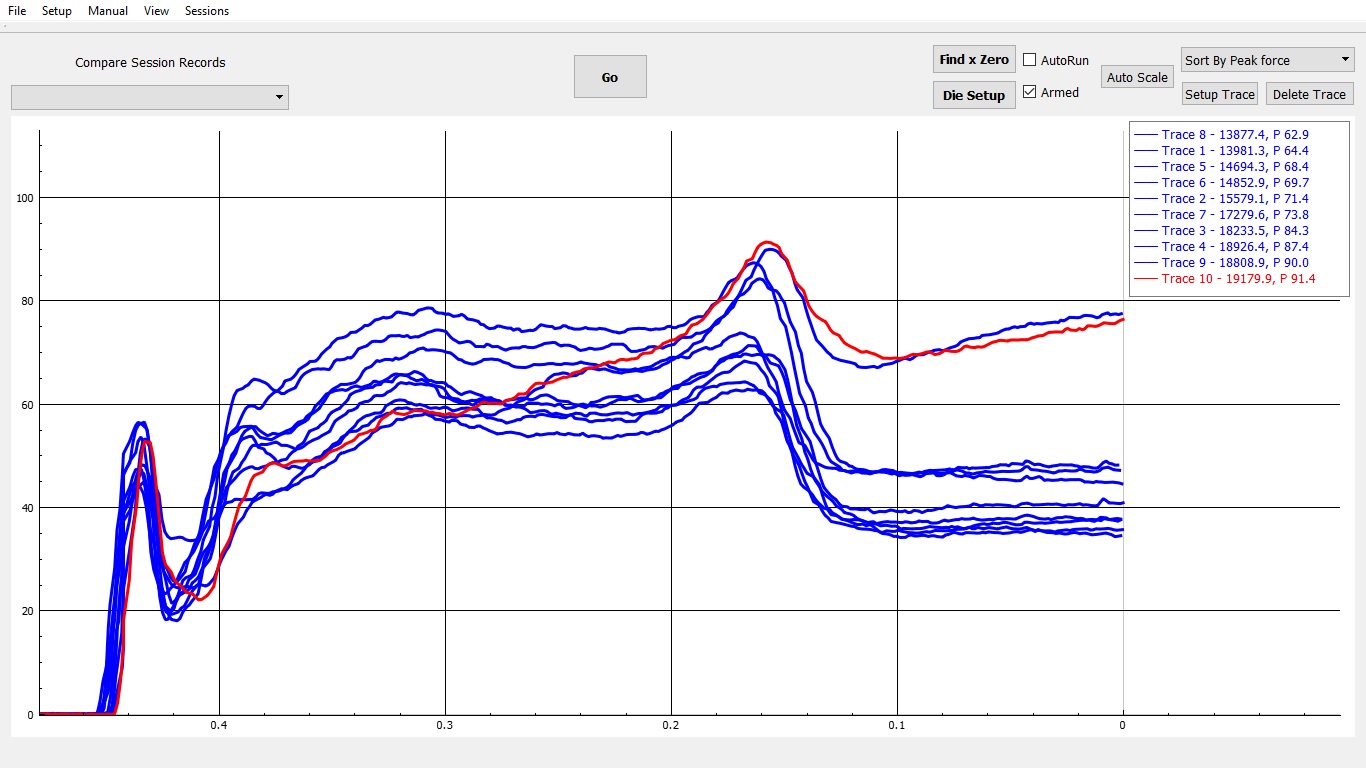

The picture below shows traces generated when seating bullets into ten virgin 308 cases. In this example, the lack of chamfering is quite distinct at the start of the trace. Considerable force is required to start the bullet entering the case mouth. Also visible is when the bottom of the bullet seats beyond the sized portion of the neck. This is indicated by the slight drop in force at the -0.16" mark on the X axis. The seating force then levels out until the bullet is fully seated.

The last two traces (the red and blue one together) distinctly show two possible "flier" loads which could be separated from the batch.

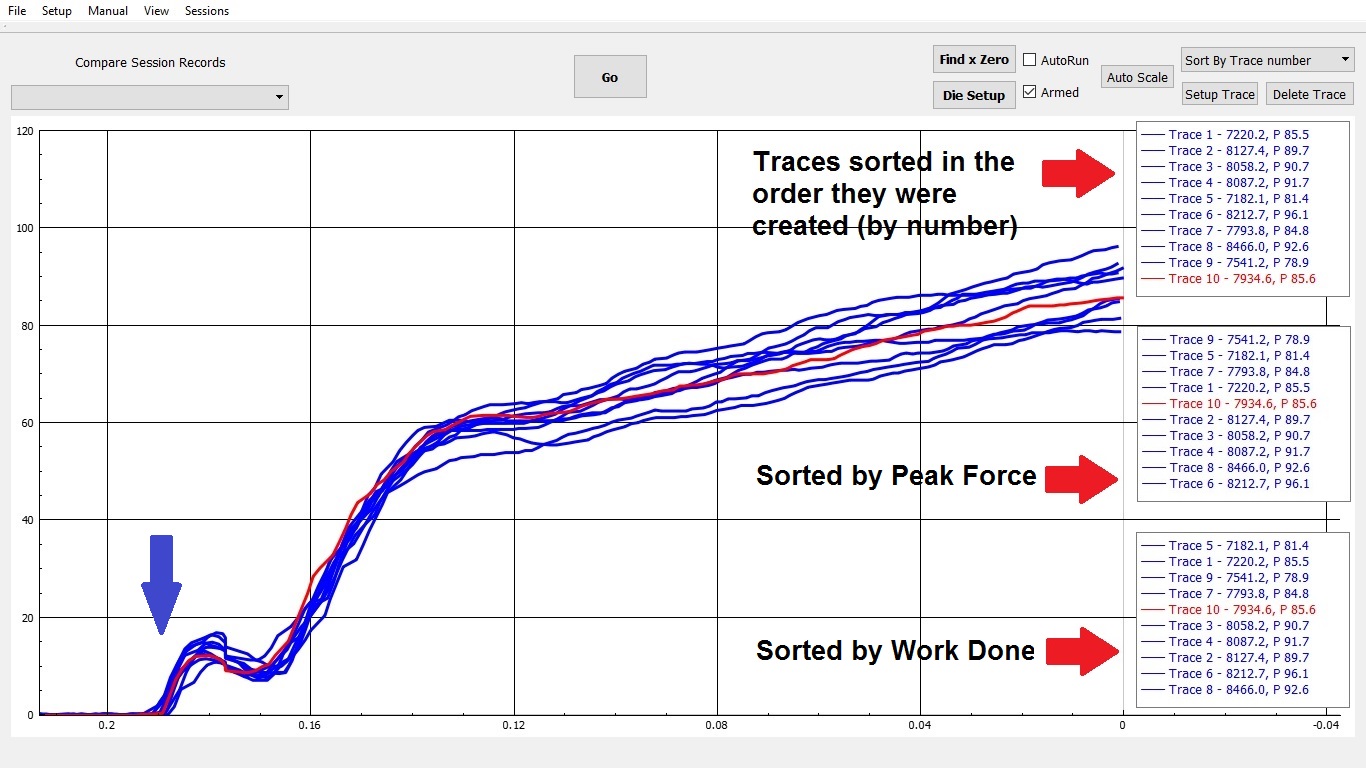

In this example below, we loaded ten 6 BRA cases. Unlike the 308 cases above, the bullets were not seated past the sized portion of the neck. Therefore the peak force was reached at the end of the seating stroke. More attention was taken when prepping the brass and the improvement in consistency is visible. Much less force was required to start the bullets entering the case mouth (indicated by the Blue arrow).

Also shown in this example by the Red Arrows is the SORT function listing the traces in order of either the order they were taken (top), the highest or Peak force that was measured (middle) or the total Work done (bottom).

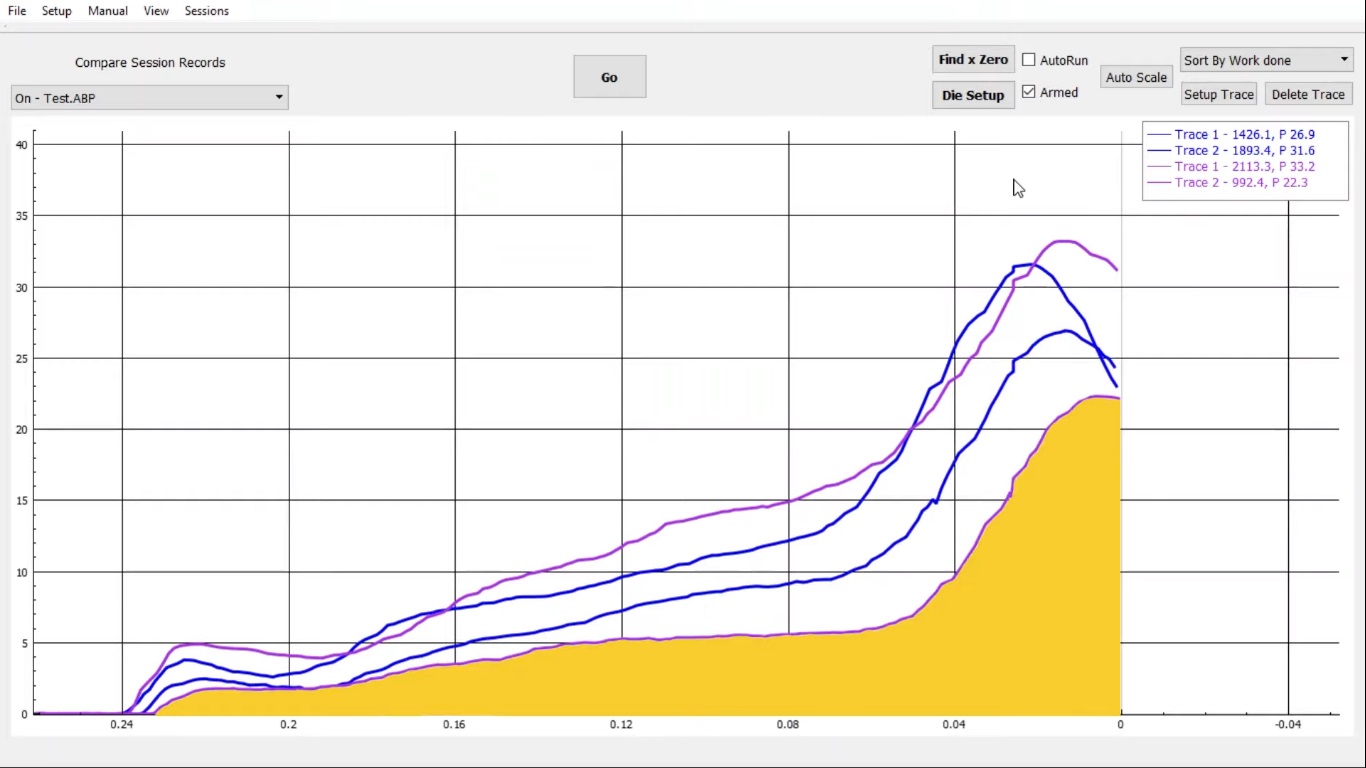

Sorting by Work Done

One of the main benefits of AMP Press is the addition of a position sensor which allows for "Total Work Done" data to be calculated.

In the below picture, this measurement is illustrated by the highlighted yellow area. In this example the trace with the lowest work done has been highlighted. This is a new and exciting metric with which to sort cartridges.

Features:

Load cell

AMP Press comes equipped with a precision load cell which delivers exact weight measurements up to 200 kilograms. The face of the load cell is surrounded by a retainer which guides the die to the center of the cell. This ensures repeatable measurements every time. The load cell is highly accurate. Minute case to case variations can be magnified and displayed in incredible detail.

The load cell face is free floating. This ensures that no binding takes place when the ram presses the die down onto load cell and that everything remains centered.

12V Motor

The ram on AMP Press is driven by a high torque, DC motor. This ensures that a repeatable stroke in both speed and force is applied to the die when seating. This removes the human error which occurs when operating conventional arbor presses. The 12V DC motor means the press can be easily powered by batteries. This allows its use in more remote locations such as at a range.

Distance sensor

The position of the ram is calculated using a position sensor, which is accurate to 0.001". This allows the distance to seat bullets to be displayed against force for the first time. This is especially useful in highlighting discrepancies such as trim length and chamfer consistency. It also allows for the calculation of "Total Work" to be applied to the plot as an option to sort by for the first time.

Bluetooth- AMP Press is Bluetooth capable allowing for wireless communication to your preferred device. Bluetooth will be enabled after the initial release of AMP Press. In the interim, computer connection will be by USB cable. Note: Both PC and Mac software is available.

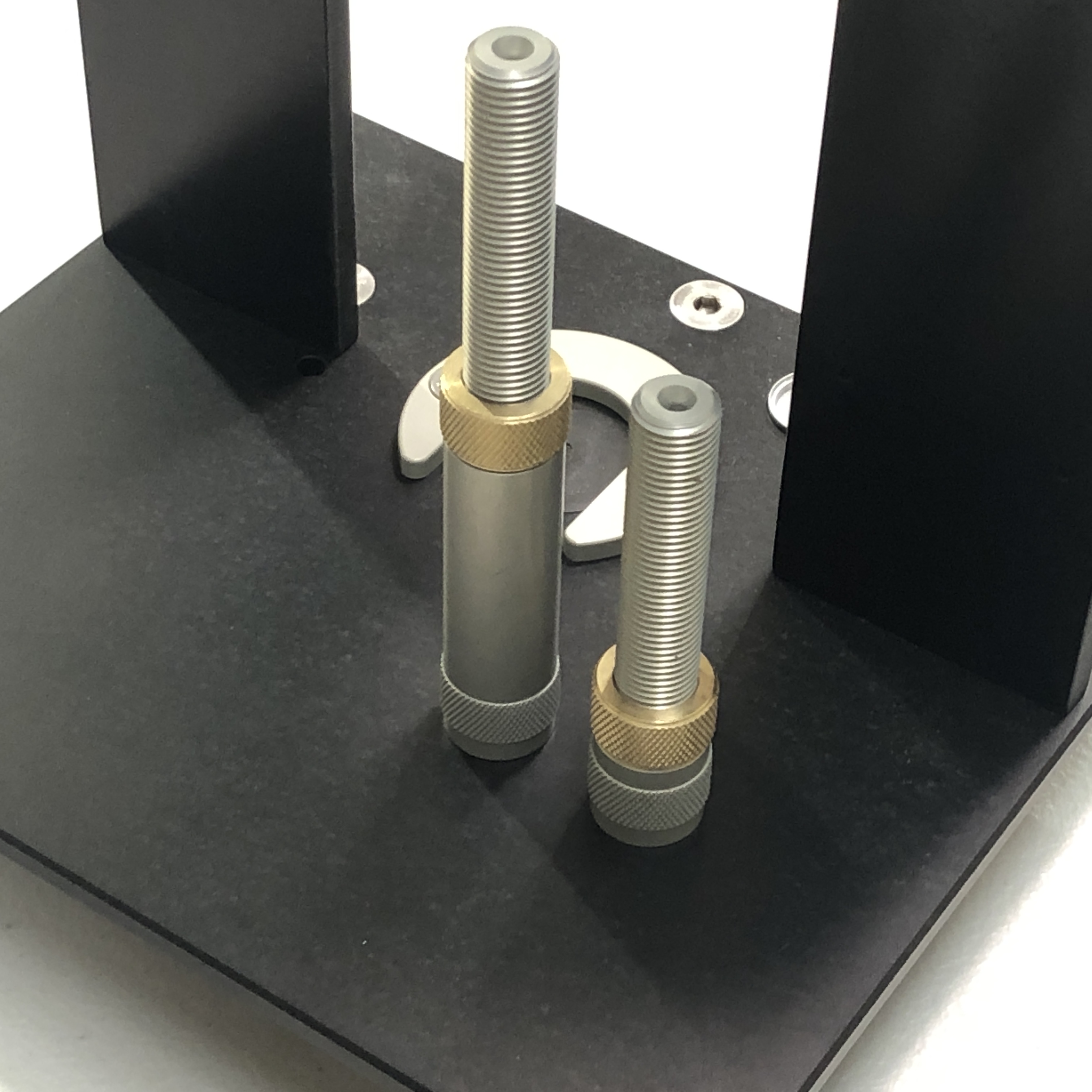

Adjustable for many die sizes- AMP Press comes with two interchangeable ram lengths. These allow for a wide range of cartridge dies to be used.

AMP Press Instructional Video